Creating a CCU10 puzzle from tin using a laser cutting machine

The CCU10 puzzle CCU10 (Computer's Choice Unique 10) is a 6-piece burr

puzzle that was discovered by Bill Cutler using a computer. It has

one solution and removing the first piece requires 10 moves. This

document describes making CCU10 from tin. The length of each piece is

about 49.3mm.

The project was inspired by a similar project by Oskar van Deventer,

where Oskar and I used my laser cutting machine to create molds for

pieces of Oskar's edge slide puzzle design.

Used Materials

-

Tin (about 0.4kg) (about 0.25kg is used in the puzzle) Tin can be

bought in several kinds. I used tin that is food-safe; it is safe

to use in cups and plates.

- 4mm MDF (a piece of 20cm by 20cm) (can be re-used)

- 6.2mm MDF (a piece of 20cm by 20cm) (destroyed)

- 200 gram / square m paper (a piece 10cm by 20cm)

- 14 bolts M3x25 (that is 3mm thick with 25mm of thread) + 14 nuts

Required tools

- Gas stove

- Small pan (not suitable for cooking food after melting tin)

- Steel brush

- File

- Small metal saw

- Some knives, screwdrivers, etc. (to remove the mold).

- Safety goggles

- Laser cutting facility

Laser cutting the mold

The laser cutting machine is an expensive device. Mine uses a 35Watt

laser which can be directed straight downward on any point of a 30cm

by 60cm surface. The machine is connected to a personal computer

running MS-Windows. To the operating system the laser cutting machine

looks like a printer. Naturally you also need a design to cut and

software that "prints" the design to the laser cutting machine.

I use self-written software, but it can also be done from AutoCad,

CorelDraw, etc.

When the laser cutting machine is cutting 6mm MDF, it removes a slot

that is about 0.1mm wide at the bottom surface and about 0.3mm wide

at the top surface of the MDF. The cut surfaces are charred but

quite smooth. To ensure that the pieces actually fit together, the

cuts from the MDF must be completely inside the

lines of the grid in which all edges of the pieces fall.

Because the thickness of my MDF stock was 6.2mm, my unit size is

6.2mm. I've made all cuts that outline the pieces 0.2mm inside this

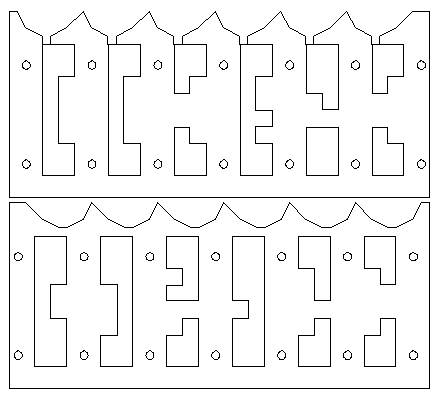

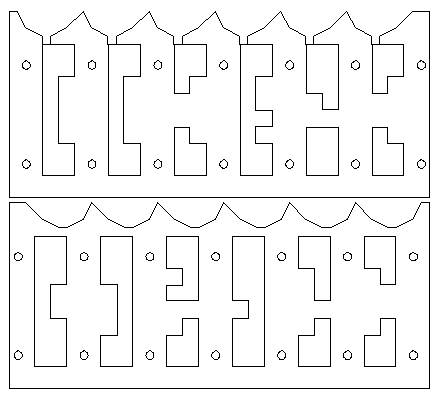

grid. The main layers of the mold are shown below:

Do not use this drawing to make your own. The

resolution is simply too low. You really need the drawing in a

vector format.

The layer shown on the bottom should be turned over and then placed

on top of the layer shown above it.

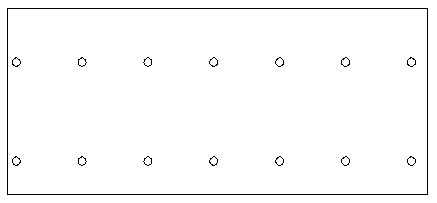

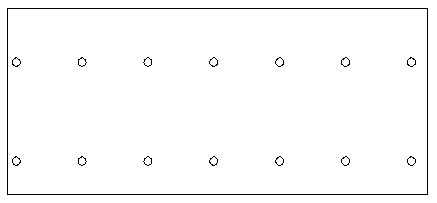

To ensure that air can escape from the mold when the tin is cast

into it, a layer of 200 grams per square meter paper is cut using

the design shown below.

This paper has the same mounting holes as the MDF. The bottom edge

goes flush with the bottom edge of the other layers of the mold. The

top edge is about 0.2mm below the top of the shapes. This creates a

narrow channel for the air to escape (and a sharp edge on the

resulting pieces that can be filed off in a second). The amazing

thing is that the paper can be reused a couple of times.

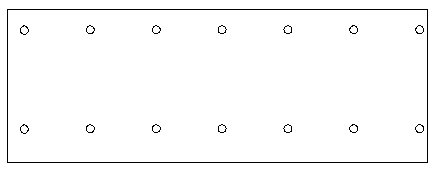

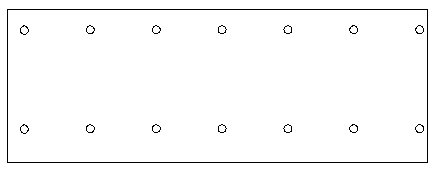

Finally two covers are needed. These are cut from 4mm MDF, but the

thickness is not very relevant. If you use thicker MDF for the

covers, you'll need longer bolts to hold the mold together. The

layout for the front and back covers is the same and shown below.

This is virtually identical to the paper layer, except that the top

edge is further above the top row of mounting holes.

Cutting the layers of the mold

All layers (including the paper one) are made with the laser cutting

machine. The photo below shows the result of cutting the two 6.2mm

pieces. Click on any of the photos for a really large version.

After the MDF is taken out of the machine, the cut out pieces can

be removed.

All layers of the mold (4mm MDF, paper, 6mm MDF, 6mm MDF, 4mm MDF)

are stacked together and aligned using five M3x25 bolts. I've

wrapped some Scotch tape around the shafts of these bolts to make

them fit snugly in the holes. This reduces the possibility for

mis-alignment to the minimum. (The other 9 bolts are put in later

and need not be wrapped with tape.) I used yellow paper.

A close up of the top of the assembled mold is shown below.

The top of the mold show the holes where the tin will be poured

in. The nuts on the bolts must be hand-tight; no tools are

required to tighten them.

Pouring the tin

The tin is heated in a small aluminum pan. The melting point of

the aluminum is much higher than the melting

point of the tin; there is little risk of melting the aluminum

of the pan. A gas stove is required to melt the tin.

Melting and pouring tin should be done with great care. This is

not something to be done by unsupervised children.

I have no photographs of the pouring process because I did this

all on my own and I couldn't take photographs while pouring.

I put a clamp on the mold to make it more stable before I poured

the tin. I slowly poured tin into the entry holes until they

overflowed, or were on the verge of overflowing. I wore safety

goggles while pouring the tin. The tin won't sputter when being

poured in a nice dry mold, but one should never take chances

with one's eyesight.

Opening and removing the mold

After pouring I waited some time to let the tin solidify and

cool down. After removing the bolts and taking off the

top cover I had the following result.

As you can see, the tin filled the mold very precisely.

It was not possible to remove the 6.2mm MDF layers of the mold

from the tin without completely destroying them. I used a knife

and a big screwdriver to carefully destroy the mold around the

pieces without damaging the pieces. (In later, similar projects,

I used the laser cutting machine to cut the wood of the mold in

small bits; the laser won't damange the tin.) After removal of

the first layer of the mold, the result looked like this.

The second layer is removed.

Removing the cast-entry points

I removed the cast entry points with a simple small metal saw and

filed off the remaining stumps. Tin is a soft metal that can

easily be sawn and filed.

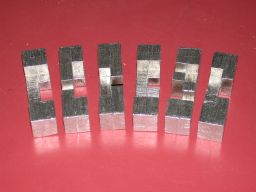

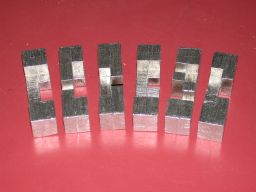

Cleaning up

After removing the cast entry points, the pieces still were a bit

stained by the resin that was emitted by the MDF and the edges

of the mold layers are rather visible. With a file I made the

mold layer edges a bit less obtrusive and using a steel brush I

removed all stains from the tin and gave the pieces a nice silvery

look. I brushed the sides of the pieces along their length axes.

The square top ends were brushed at 45 degree angles (with respect

to the sides of the top square). I expect that the silvery look

will wear off somewhat when the surface of the tin oxidizes.

Assembled puzzle

Finally I assembled the puzzle. The pieces have a nice fit; I have

judged the thickness of the cut made by the laser well. The

assembled puzzle is shown below.

Peter Knoppers - (initial version: 2003-Sep-14, last edited: 2019-Jul-19)